Table of Contents

Overview of Cigarette Filter Rod Technologies and Trends

The cigarette filter rod is no longer a simple functional component—it has become a critical element influencing smoke quality, regulatory compliance, brand identity, and consumer preference. As cigarette markets evolve worldwide, manufacturers increasingly rely on advanced filter rod technologies to differentiate products while maintaining production efficiency and consistency. From standard mono acetate designs to highly engineered specialty filters, understanding the full range of cigarette filter rod types is essential for manufacturers operating in competitive global markets.

This guide provides a comprehensive overview of the major cigarette filter rod types used by global manufacturers, explaining how each design supports specific performance goals, market demands, and production requirements.

The Role of Filter Rods in Modern Cigarette Manufacturing

In modern cigarette production, the filter rod serves multiple functions simultaneously. It regulates smoke flow, reduces tar and particulate matter, influences flavor delivery, and directly impacts draw resistance and mouthfeel. Beyond performance, filters also contribute to visual differentiation and brand recognition, especially in premium and customized cigarette segments.

As regulations tighten and consumer expectations rise, manufacturers must carefully select filter rod structures that balance filtration efficiency with smooth airflow and stable production performance. This has led to the development of a wide range of filter rod designs tailored to specific applications and regional preferences.

Understanding Cigarette Filter Rod Construction and Function

Most cigarette filter rods are constructed using cellulose acetate tow as the primary filtration medium, combined with plug-wrap paper and optional internal segments. The performance of a filter rod depends on several interrelated factors, including tow density, crimping structure, ventilation patterns, and overall rod geometry.

Airflow management plays a crucial role in filter performance. Properly engineered filter rods maintain consistent pressure drop while allowing controlled smoke dilution. Any imbalance in these parameters can affect smoking experience and machine efficiency, making precision manufacturing essential for large-scale production.

Mono Acetate Filter Rods: The Industry Standard

Mono acetate filter rods remain the most widely used filter type in global cigarette manufacturing. Their popularity stems from their simplicity, reliability, and compatibility with high-speed production lines. Made entirely from cellulose acetate tow, these filters provide balanced filtration, stable firmness, and predictable draw resistance.

Mono acetate filters are commonly used in mainstream cigarette brands and high-volume production environments. Their consistent performance and cost efficiency make them an ideal starting point for manufacturers, particularly in markets where standard smoking characteristics are preferred.

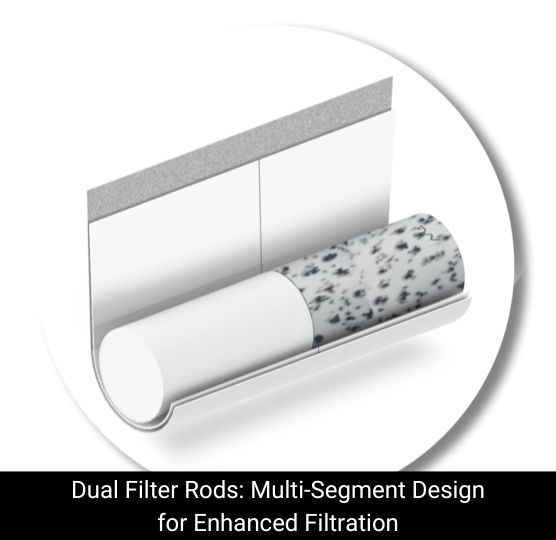

Dual Filter Rods: Enhanced Filtration Through Multi-Segment Design

Dual filter rods incorporate two distinct filter segments within a single rod, allowing manufacturers to combine different filtration functions. Common configurations include acetate combined with charcoal, multi-density acetate, or flavor-enhancing segments.

By separating filtration tasks across segments, dual filter rods offer improved control over tar reduction, smoke smoothness, and flavor refinement. These designs are frequently used in premium cigarettes, low-tar variants, and products targeting consumers seeking a more refined smoking experience.

Recessed Filter Rods: Mouth-End Design for Smoother Smoke

Recessed filter rods feature a hollow cavity at the mouth end of the filter. This structural design allows smoke to expand slightly before reaching the smoker, resulting in a cooler and smoother sensation. The recess zone can also help reduce perceived harshness and improve overall mouthfeel.

Recessed filters are often positioned as premium solutions and may be combined with other filter technologies such as charcoal segments or capsules to further enhance performance and differentiation.

Our Other Product

Inner Shaped Filter Rods (Tube Filter Rods)Capsule Filter Rods (Click Filter Rods): Flavor-Activated Filtration

Capsule filter rods, commonly known as click filter rods, contain one or more breakable capsules embedded within the filter structure. When pressed, these capsules release flavor into the smoke stream, allowing smokers to activate flavor on demand.

This interactive experience has made capsule filters extremely popular in many global markets. Manufacturers can customize capsule size, placement, and flavor type to suit specific brand strategies, making capsule filter rods a powerful tool for product differentiation.

Flavored Filter Rods: Continuous Aroma Delivery Without Capsules

Unlike capsule filters, flavored filter rods deliver aroma continuously throughout the smoking experience. Flavor compounds are applied using controlled spraying or infusion techniques, ensuring stable and uniform flavor release.

These filters are particularly suited for aromatic cigarettes and premium blends where subtle, consistent flavor enhancement is preferred over click activation. Flavored filter rods also offer advantages in markets where capsule usage may be restricted or less popular.

Inner Shaped Filter Rods (Tube Filter Rods): Airflow-Controlled Designs

Inner shaped filter rods, often referred to as tube filter rods, feature hollow cores or engineered airflow channels within the filter. These structures help regulate smoke flow, reduce tar delivery, and maintain stable pressure drop.

Tube filters are commonly used in low-tar cigarettes, slim formats, and products designed for optimized ventilation. Variations such as star-shaped, circular, or hexagonal inner structures allow manufacturers to fine-tune airflow behavior while maintaining filter firmness and visual appeal.

Read Our Article

Specially Designed Cigarette Filter RodsOuter Shaped Filter Rods: Visual and Tactile Differentiation

Outer shaped filter rods are designed with grooved, embossed, or sculpted outer surfaces that enhance both appearance and tactile feel. These designs help cigarette brands stand out visually while offering a premium mouth-end experience.

In addition to aesthetics, outer shaping can influence airflow behavior at the filter surface, contributing to improved smoke interaction. These filters are widely used in premium and design-led cigarette products.

Specialty and Customized Filter Rod Solutions

Beyond standard categories, many manufacturers opt for customized filter rod solutions that combine multiple technologies into a single structure. These may include multi-segment filters with capsules and charcoal, shaped designs with flavor infusion, or hybrid structures tailored to specific market needs.

Customization allows brands to align filter performance with target consumer preferences, regulatory requirements, and production constraints. Successful customization requires close collaboration between manufacturers and experienced filter suppliers.

How Global Manufacturers Choose the Right Filter Rod Type?

Selecting the appropriate filter rod type involves balancing several factors, including desired smoking experience, production compatibility, regulatory environment, and cost considerations. Manufacturers must also account for regional differences in consumer preference and machine configuration.

A well-chosen filter rod supports brand positioning while ensuring consistent quality and efficient production across large volumes.

Our Other Product

Recessed Filter RodsThe Importance of Working with an Experienced Filter Rod Manufacturer

As filter designs become more complex, the role of the filter rod manufacturer becomes increasingly critical. Precision engineering, strict quality control, and scalable production capability are essential for maintaining performance consistency across global markets.

Truewell supports cigarette manufacturers worldwide by offering a comprehensive portfolio of standard and specialty filter rods, backed by strong engineering expertise and export-ready production. With a focus on customization, production stability, and global supply reliability, Truewell helps brands transition from conventional filters to advanced, market-driven solutions with confidence.

Future Trends in Cigarette Filter Rod Technology

The future of cigarette filter technology is expected to emphasize greater customization, premium design, and performance optimization. As consumer expectations evolve and regulations continue to shape product development, filter rods will remain a key area of innovation.

Manufacturers that invest in advanced filter solutions and partner with experienced suppliers will be best positioned to adapt to these changes while maintaining quality, compliance, and brand differentiation.

Choosing the Right Filter Rods for Global Success

Understanding the full range of cigarette filter rod types is essential for manufacturers competing in today’s global markets. From standard mono acetate filters to advanced specialty designs, each filter type plays a strategic role in shaping smoke quality, brand identity, and production efficiency. With the right filter technology and manufacturing partner, cigarette brands can meet evolving market demands while maintaining consistent performance at scale.

Frequently Asked Questions (FAQs) on Cigarette Filter Rods

What are the main types of cigarette filter rods used by manufacturers?

Cigarette manufacturers commonly use mono acetate, dual segment, recessed, capsule, flavored, inner shaped (tube), and outer shaped filter rods. Each type is designed to achieve specific goals such as filtration efficiency, airflow control, flavor delivery, or premium brand differentiation.

How do manufacturers select the right filter rod type for different markets?

The choice of filter rod depends on regional smoking preferences, regulatory requirements, and brand positioning. Manufacturers evaluate factors such as tar delivery targets, draw resistance, flavor expectations, and machine compatibility before selecting or customizing a filter structure.

Are specialty filter rods compatible with high-speed cigarette production?

Yes. When properly engineered, specialty filter rods are designed to operate reliably on modern, high-speed cigarette-making machines. Consistent pressure drop, accurate segment alignment, and stable materials ensure smooth production without compromising efficiency.

What role does filter rod design play in brand differentiation?

Filter rod design significantly influences the visual appearance, mouthfeel, and smoking experience of a cigarette. Features such as capsules, shaping, recess zones, or decorative elements help brands create distinctive products that stand out in competitive markets.

Why is it important to work with an experienced cigarette filter rod manufacturer?

An experienced filter rod manufacturer provides technical expertise, strict quality control, and scalable production capabilities. This ensures consistent filter performance, regulatory compliance, and reliable supply for global cigarette brands.